Sewer Main and Lateral Grouting

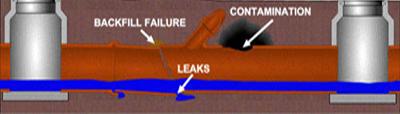

Sewer main and lateral pipe grouting is a viable rehabilitation technique utilized to seal out runoff and groundwater seepage into structurally sound pipe. Grouts have a variety of chemical formulas that are matched to be compatible with local soil conditions and pipe materials.

Prior to installing the grouting material the pipe is thoroughly cleaned. Once the pipe is clean the grout is applied through the inside of the pipe with a machine called a packer. The grout is injected out through the pipe defect or open joint and into the surrounding soil matrix and the pipe material. The injected material bonds with the soil and pipe material forming a waterproof seal.

Once the sewer mains are grouted a similar process is used to grout the building service laterals where they connect to the sewer main. The building service laterals are grouted in the same manner as the sewer mains. The equipment used for grouting the building lateral is specialized for this purpose and is not the same as the equipment for sewer main grouting.

Grouting can be accomplished in a few hours, and does not disturb the ground or paving surface. Normally there will be no interruption to service.

[Image]

| [Image]

| [Image]

|

Lining Main and Lateral

Sewer main lining is a technique that installs a new pipe into an old worn pipe requiring structural reinforcement. Prior to installing a liner the host pipe will be thoroughly cleaned and inspected using Closed Circuit Televising (CCTV) to determine the pre lining conditions.

A custom sized liner is fitted into the sewer main and positioned into place. The liner is then expanded using a medium such as hot water and pushed firmly against the old pipe. The expanded liner is given time to cure thereby forming a new pipe that has no joints or seams and a very smooth interior surface.

After the main is lined, the opening for the building lateral pipe is reinstated.

Service laterals may be lined before or after the sewer main has been lined. The lateral liner that extends from the sewer main to the sewer lateral cleanout located at the property line. If a sewer cleanout does not exist at the property boundary, one will be installed prior to the lateral lining process, free of charge. Service laterals are lined in the same manner as sewers mains, but with equipment made especially for the service lateral.

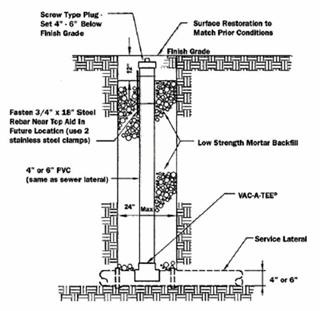

If a cleanout does not exist at the property line a vacuum excavation method may be used to install one. As seen in the picture below, a 24” diameter hole is created by vacuuming out to the depth of the service lateral and installing a vertical cleanout pipe that will allow maintenance access in the future.

If a cleanout can not be installed using the vacuum extraction method, then the traditional open cut method becomes necessary. The open cut method normally requires an approximately 5-foot by 5-foot pit.

If the service lateral cannot be brought to code by the lining method, the contractor will use an open-trench method to install a clean-out and new service lateral. In the event that the open-trench method is used, trees, shrubbery, sidewalks, curbs and gutters may be disturbed. WSSC Water will, at no cost its customers, restore the disturbed area as close to its original condition as possible when the construction activities are completed. Trees that must be removed may be replaced with tree saplings.

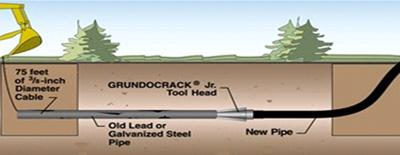

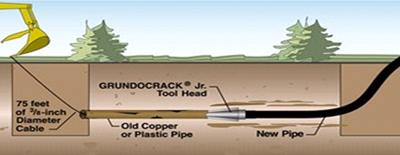

Pipe Bursting

Pipe Bursting is a rehabilitation process by which a bursting unit splits and/or fractures the existing pipe while simultaneously installing a new pipe. This method is used as an alternative to open cut replacement in areas where existing site conditions such as soil type, line and grade, number of service lateral connections, and existing pipe materials are favorable. Most of the work associated with this process is underground, however small pits are necessary to reinstate service laterals as well as for pipe bursting equipment entry and exit.

A new pipe is installed by pushing or pulling a bursting unit along the length of pipe from an entry point to an exit point while the equipment pulls a new pipe forward as it moves. Pipe bursting is a quick process compared to open cut renewal. The pipe bursting of the main sewer should only take a day, however excavations for the service laterals, and the entry and exit pits can make the whole process last several weeks.

If the configuration of the service lateral being rehabilitated is favorable, the lateral pipe will also be burst from the main to the existing cleanout located at the property boundary. If it is not practical to burst the service lateral, a trench will be excavated to install the new service lateral pipe. If there is not currently a cleanout at the property line, one will be installed as part of the process.

It may be necessary to ask customers to refrain from using water for a short period during the reconnection of the lateral pipe to the newly installed main. Some trees, sidewalks, and paving may be disturbed.

Open Cut Renewal

Open cut excavation is chosen when existing conditions make excavation and replacement the only solution. There are two ways to complete this work, same trench replacement or pipe relocation. Same trench replacement is the installation of a new pipe into the existing trench after the old pipe is removed.

Pipe relocation is the realignment of the existing sewer. The realignment of a sewer requires the generation of new plans and their approval. Pipe relocation also requires coordination with other utilities and town meetings to notify the community of how the work will affect the neighborhood and what disruptions they may expect. This work may take several weeks to complete and involves disruption of surface cover and trees.